The Importance of Regular Diesel Engine Oils Changes on Construction Sites

Construction sites rely heavily on the performance and durability of heavy machinery to keep projects on schedule and within budget. Diesel-powered equipment such as excavators, bulldozers, cranes, and loaders endure extreme working conditions, making their maintenance a top priority. One of the most critical yet often overlooked aspects of equipment upkeep is the regular change of Diesel Engine Oils. This simple maintenance task can significantly influence the longevity, efficiency, and reliability of construction machinery. At EVISCO, we understand the crucial role that diesel engine oils play in protecting your equipment investments and maximizing productivity on construction sites.

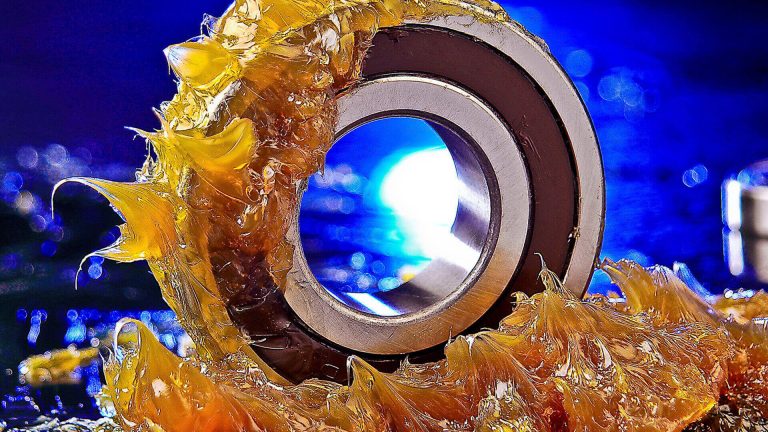

Understanding Diesel Engine Oils and Their Role

Diesel engine oils are specially formulated lubricants designed to reduce friction, wear, and heat in diesel engines. Unlike gasoline engines, diesel engines operate under higher pressures and temperatures, which demands robust protection. The oil circulates through the engine, creating a protective film on metal surfaces, minimizing direct contact and preventing damage caused by friction and corrosion. Furthermore, diesel engine oils help to clean the engine by suspending contaminants and preventing sludge buildup. Without proper lubrication, the engine components can quickly deteriorate, leading to costly repairs and downtime.

Why Regular Diesel Engine Oils Changes Matter

Changing diesel engine oils regularly is not just about replacing old oil. It is about ensuring optimal engine performance and extending the service life of expensive machinery. Over time, engine oil degrades due to heat, oxidation, and contamination from dirt and combustion byproducts. As oil breaks down, it loses its ability to lubricate effectively, leading to increased wear and tear on engine parts.

On construction sites where machines often operate in dusty, harsh environments and endure long hours of heavy use, the oil can become contaminated faster than in other settings. Regular oil changes flush out harmful particles and replenish the oil’s protective properties, keeping engines running smoothly and reducing the risk of breakdowns.

Impact of Neglecting Diesel Engine Oils Changes

Ignoring timely diesel engine oil changes can have severe consequences for construction equipment. Worn-out oil increases friction between moving parts, accelerating engine wear and potentially causing catastrophic failure. Contaminated oil can clog oil passages and filters, restricting lubrication flow and causing overheating. Overheated engines may suffer from warped components or cracked cylinders, necessitating expensive repairs or replacements.

Additionally, neglected oil changes contribute to reduced fuel efficiency. As friction rises inside the engine, more fuel is required to maintain the same level of power output, raising operating costs significantly. For construction companies operating on tight margins, this inefficiency can erode profitability and lead to frequent project delays.

Signs That Indicate It’s Time to Change Diesel Engine Oils

Construction managers and equipment operators should be vigilant for signs that diesel engine oils need changing. Common indicators include dark, thick, or gritty oil when checked on the dipstick, unusual engine noises such as knocking or ticking, decreased engine power, and increased exhaust smoke. Some modern machinery is equipped with oil life monitoring systems that alert operators when oil quality declines. Responding promptly to these signals prevents minor issues from escalating into costly failures.

Choosing the Right Diesel Engine Oils for Construction Equipment

Selecting the correct diesel engine oils is essential for protecting heavy-duty machinery. Oils vary based on viscosity, additive packages, and certification standards. Construction equipment manufacturers typically recommend specific oil grades and types that meet the demands of their engines. Using oils that conform to industry standards such as API CJ-4 or newer ensures compatibility and optimal performance.

At EVISCO, we offer premium diesel engine oils formulated for construction applications. These oils provide superior oxidation stability, detergency, and wear protection, making them ideal for the intense operating conditions faced on job sites. Choosing the right oil combined with regular changes maximizes engine protection and helps maintain warranty compliance.

Benefits of Regular Diesel Engine Oils Changes

Regularly changing diesel engine oils offers several long-term benefits for construction projects. Equipment longevity improves as engines experience less wear and tear, reducing the frequency of repairs and replacements. Consistent oil changes also contribute to better fuel economy, lowering operational expenses and environmental impact.

Moreover, well-maintained engines run cooler and more efficiently, minimizing downtime caused by overheating or mechanical failures. This reliability directly translates to increased productivity and adherence to project timelines. Furthermore, maintenance records showing regular oil changes can increase resale value when upgrading equipment.

Best Practices for Diesel Engine Oils Maintenance on Construction Sites

Implementing a proactive maintenance schedule is key to optimizing the benefits of diesel engine oils. Construction site managers should develop a routine inspection and oil change plan based on manufacturer guidelines and machine usage intensity. Keeping detailed logs of oil change dates, types of oils used, and machine hours helps in tracking maintenance history and anticipating future needs.

Training equipment operators to perform daily checks on oil levels and quality can catch early signs of oil degradation or leaks. Additionally, investing in quality oil filters and replacing them during oil changes ensures contaminants are effectively removed. Combining these best practices with EVISCO’s high-quality diesel engine oils guarantees maximum engine protection and site efficiency.

Conclusion: Protect Your Construction Investments with Timely Diesel Engine Oils Changes

Regular diesel engine oils changes are indispensable for maintaining the health and performance of construction machinery. They not only protect engines from wear and corrosion but also enhance fuel efficiency and reduce costly downtime. For construction professionals aiming to extend equipment lifespan and optimize project productivity, adhering to a disciplined oil maintenance schedule is a wise investment.

At EVISCO, we provide expert guidance and premium diesel engine oils tailored to the demanding needs of construction sites. Prioritize regular oil changes today to safeguard your heavy machinery, improve operational efficiency, and ultimately secure the success of your construction projects. Remember, well-lubricated engines are the backbone of every thriving construction site.