Essential Guide to Electromagnetic Shielding Materials: Types, Applications, and Benefits

Understanding Electromagnetic Shielding Materials

Electromagnetic shielding materials play a crucial role in protecting electronic devices and sensitive components from electromagnetic interference (EMI). As technology advances and the prevalence of electronic devices increases, the need for effective shielding becomes increasingly critical. Electromagnetic shielding materials are designed to block or reduce electromagnetic fields, safeguarding various applications across industries. In this article, we will explore the concept of electromagnetic shielding, its importance, applications, types of materials used, mechanisms of effectiveness, and the latest trends in this essential field. For those interested in electromagnetic shielding materials, understanding these elements will provide a solid foundation for choosing the right products for specific needs.

What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances specifically designed to obstruct magnetic and electric fields. They work by reflecting and absorbing electromagnetic radiation, preventing it from interfering with nearby electronic systems. These materials can be composed of various elements, including metals and polymers, and are utilized in a variety of form factors such as sheets, foams, and coatings. A common use is in the construction of protective enclosures for sensitive electronic devices, ensuring that they operate efficiently without interference from external sources.

Importance of EMI Shielding

The importance of EMI shielding cannot be overstated, especially in a world increasingly reliant on technology. Significant issues, like data loss, device malfunctions, and even safety concerns, can arise from unprotected electronic systems. The following are key reasons why EMI shielding is essential:

- Ensures Device Integrity: Helps maintain the performance and reliability of electronic devices by preventing external interference.

- Protects Sensitive Data: In environments like hospitals, data integrity is critical; EMI shields protect patient information and other sensitive data from unauthorized access.

- Enhances Safety: In industries such as aviation or medical, effective shielding can prevent catastrophic failures caused by EMI.

- Meets Regulatory Standards: Many industries must adhere to strict EMI regulations; using proper shielding materials helps ensure compliance.

Applications of Electromagnetic Shielding Materials

Various industries leverage electromagnetic shielding materials for diverse applications. Here are some notable examples:

- Consumer Electronics: Smartphones, laptops, and other devices use EMI shielding to offer users uninterrupted performance.

- Medical Devices: MRI machines, pacemakers, and monitoring equipment require effective shielding to prevent data corruption and ensure patient safety.

- Aerospace: Aircraft systems depend on shielding materials to protect sensitive electronics and communication systems from radiation and external interference.

- Automotive: Modern vehicles incorporate numerous electronic controls that need shielding to function properly, particularly those involved in navigation and safety systems.

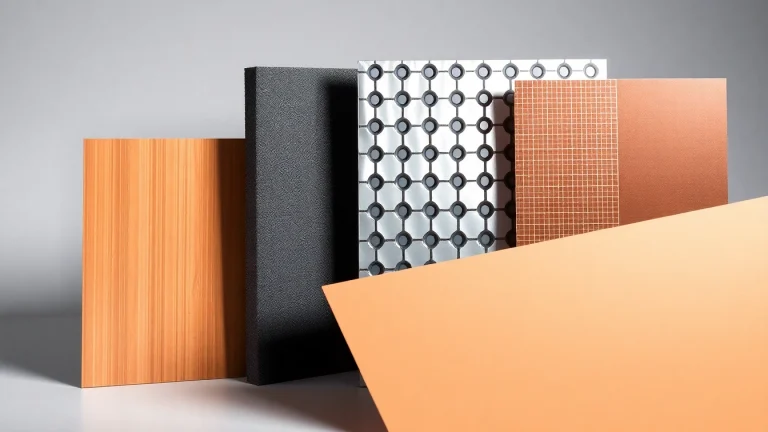

Types of Electromagnetic Shielding Materials

Metals Used in EMI Shielding

Metallic materials are the most common choices for electromagnetic shielding due to their high conductivity and effectiveness. The primary metals used include:

- Copper: Known for its exceptional conductivity, copper serves as a leading metal in EMI shielding applications, efficiently blocking both electric and magnetic waves.

- Aluminum: Lighter than copper but still effective, aluminum is often used in lighter shielding applications, including lightweight enclosures and shields.

- Steel: Steel’s strength makes it ideal for robust applications where durability is necessary. It is often used in medical and military equipment.

- Nickel: This metal demonstrates excellent corrosion resistance, making it suitable for environments where forming a shield must withstand challenges.

Flexible Shielding Solutions

Flexible shielding materials have gained popularity due to their adaptability and ease of use in various applications. Some common flexible shielding solutions include:

- Metal Foils: Used in various configurations, metal foils can be shaped to fit specific components, making them highly versatile.

- Conductive Fabrics: These materials can be easily integrated into clothing or gear, making them ideal for military applications and wearable technology.

- Coatings: Metallic inks and paints can be applied to surfaces to provide EMI shielding while maintaining the aesthetic of the device.

- Conductive Adhesive Films: These films can be implemented to bond components while providing a conductive path, enhancing both structural integrity and EMI protection.

Non-Metallic Shielding Options

While metals are predominant, various non-metallic materials also offer effective EMI shielding properties. These include:

- Conductive Polymers: These synthetic materials provide a unique combination of flexibility and conductivity, often used in electronic housings.

- Carbon-Based Materials: Made from graphite or carbon fibers, these materials offer lightweight protection with effective conductivity.

- Ceramics: Certain ceramic composites are used for high-temperature applications and can provide a robust shield without the weight of metals.

- Cement and Composites: In construction applications, specially formulated cement can be mixed to provide shielding in homes and buildings.

How Electromagnetic Shielding Materials Work

Mechanisms of Shielding Effectiveness

The effectiveness of electromagnetic shielding materials is determined by several mechanisms, primarily:

- Reflection: When electromagnetic waves encounter a conductive material, a significant portion of the wave is reflected, preventing it from penetrating the material.

- Absorption: Some materials can absorb electromagnetic radiation, transforming the energy into heat and thus reducing the intensity of waves passing through.

- Multiple Layering: Combining different materials can enhance shielding effectiveness by utilizing the strengths of each material, thereby reducing the transmission of electromagnetic waves through various interactions.

Factors Affecting Shielding Performance

Numerous factors can influence the performance of electromagnetic shielding materials, including:

- Material Thickness: Generally, the thicker the shielding material, the better the performance, as it enhances both reflection and absorption.

- Frequency of Electromagnetic Waves: Different materials may perform better at specific frequencies, so it’s crucial to match the material properties with wave frequencies in the specific application.

- Surface Texture: The surface conditions (smoothness, roughness) can affect reflection and absorption efficiencies, contributing to overall shielding performance.

- Environmental Factors: Temperature, humidity, and presence of contaminants can alter the performance characteristics of shielding materials.

Testing Methods for Shielding Materials

To ensure the effectiveness of electromagnetic shielding materials, various testing methodologies are employed, including:

- Shielding Effectiveness Tests: These assess how much electromagnetic energy is blocked by the material, often expressed in decibels (dB).

- Near Field Scanning: This technique involves measuring electromagnetic fields close to the shield to determine how effectively the material is performing.

- Return Loss Measurements: Evaluating how much incident energy is reflected back provides insight into the shielding performance of materials.

Choosing the Right Electromagnetic Shielding Material

Considerations for Material Selection

Selecting the right electromagnetic shielding material requires careful consideration of several factors:

- Application Requirements: Assess the specific needs such as flexibility, weight, and thickness based on application requirements.

- Cost Effectiveness: Evaluate the balance between performance and cost; higher performance often comes at a premium.

- Environmental Conditions: Identify any special environmental challenges such as exposure to corrosive elements or high temperatures that the shielding material must withstand.

Common Mistakes to Avoid

When selecting electromagnetic shielding materials, avoiding common pitfalls can lead to better outcomes:

- Ignoring Frequency Considerations: Not all materials are effective across all frequencies; ensure proper match between material properties and electromagnetic frequencies.

- Underestimating Material Thickness: Selecting materials that are too thin may not provide necessary protection.

- Overcomplicating Solutions: Sometimes simpler solutions are more effective; don’t over-engineer the design unnecessarily.

Best Practices for Implementation

Implementing electromagnetic shielding materials efficiently involves adhering to best practices:

- Proper Installation: Ensure any shielding materials are installed correctly to maximize effectiveness; gaps or improperly mounted materials can severely diminish performance.

- Regular Testing: Periodically test and inspect shielding materials and systems to ensure long-term effectiveness.

- Collaborate with Experts: Engaging professionals can provide insights into the best materials and methods for specific applications.

Future Trends in Electromagnetic Shielding

Innovations in Shielding Technology

The field of electromagnetic shielding is evolving, with new technologies set to reshape the market:

- Smart Materials: Innovations in materials that can adapt to varying conditions and frequencies may soon provide dynamic shielding capabilities.

- Nanotechnology: Developments in nanomaterials can lead to lighter and more efficient shielding solutions with enhanced performance characteristics.

- Integrative Solutions: Design approaches integrating shielding with other functionalities (e.g., thermal management) are becoming more commonplace.

Eco-Friendly Shielding Materials

As sustainability becomes a priority, the industry is also focusing on environmentally friendly materials:

- Recyclable Materials: Advances are enabling the creation of shielding materials that maintain performance while being recyclable.

- Biodegradable Options: Research into biodegradable shielding materials can meet environmental standards without sacrificing effectiveness.

Impact of Advancements on Industry Applications

The advancements in EMI shielding will significantly enhance how industries approach electromagnetic challenges, improving performance, compliance, and environmental impacts in sectors from medical to consumer electronics. As manufacturers explore new technologies, the potential for better performance, reduced costs, and improved safety is considerable.