Essential Insights into the Functionality and Applications of Pneumatic Vacuum Pumps

Understanding Pneumatic Vacuum Pumps

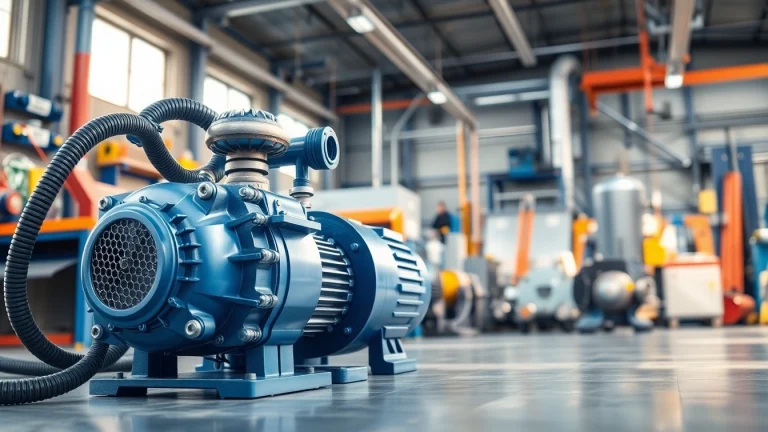

Pneumatic vacuum pumps are versatile devices that utilize compressed air to generate a vacuum, serving as crucial tools across various industries. By creating a low-pressure environment, these pumps facilitate processes such as material handling, packaging, and even the medical field’s suction requirements. As industries continuously strive for efficiency, adopting advanced technologies like pneumatic vacuum pumps is essential. This article will delve deep into the functionality, types, advantages, best practices for selection, and future trends of pneumatic vacuum pumps, offering a comprehensive overview of their significance in today’s industrial landscape.

What is a Pneumatic Vacuum Pump?

A pneumatic vacuum pump operates using compressed air, which is directed through a specialized mechanism to create negative pressure. Unlike electric pumps, pneumatic models are powered by air compressors, making them energy efficient and reducing reliance on electrical systems. These pumps can generate suction that is ideal for various applications, ranging from assembly lines to laboratory settings. The pneumatic vacuum pump plays a pivotal role in automating tasks that require the lifting, moving, or holding of components securely.

How Pneumatic Vacuum Pumps Operate

The operational principle of pneumatic vacuum pumps centers on fluid mechanics, specifically using the Venturi effect. Compressed air passes through a constricted area, leading to a drop in pressure on one side (the suction side). This pressure differential creates a vacuum, allowing the pump to draw in air or other materials from the surrounding environment. The cycle can be divided into several key stages:

- Compression: Air is compressed using a standard air compressor.

- Venturi Effect: The compressed air travels through a nozzle, where its velocity increases and pressure decreases, generating suction.

- Material Collection: The pump collects air or materials into a chamber, depending on the application.

- Discharge: Any excess air or material is expelled through an outlet, allowing continuous operation.

Applications of Pneumatic Vacuum Pumps in Industries

Pneumatic vacuum pumps find applications across various industrial sectors, including:

- Automotive: Used for brake bleeders and fluid transfer systems.

- Food and Beverage: Essential in vacuum packaging processes that increase shelf life.

- Medical: Utilized in suction devices for surgeries and patient care.

- Manufacturing: Employed in automation for material handling and assembly line processes.

- Textiles: Used in fabric handling systems to ensure precise material alignment during cutting.

Types of Pneumatic Vacuum Pumps

Single Stage vs Multi Stage Pumps

When it comes to pneumatic vacuum pumps, they can generally be categorized into single-stage and multi-stage systems. The choice between these two types depends largely on the required application and vacuum levels needed.

Single Stage Pumps: These are designed to produce a vacuum in a single step. They tend to be less expensive and simpler in construction, making them suitable for applications that require lower vacuum levels and moderate suction capabilities.

Multi-Stage Pumps: As the name suggests, multi-stage pumps operate through multiple compression stages to achieve higher vacuum levels. They offer improved efficiency and are better suited for demanding applications, such as scientific research or industrial processes that require deep vacuum levels.

Venturi Pneumatic Vacuum Pumps Explained

Venturi vacuum pumps utilize the principles of the Venturi effect by passing compressed air through a tapered nozzle that reduces the pressure on the outlet side. This design not only makes them compact and easy to integrate into systems but also enables them to function without electrical power. Their ease of operation and reliability has made them particularly popular in settings where space and power constraints exist.

Pneumatic Vacuum Generators Overview

Pneumatic vacuum generators are a specific type of pneumatic vacuum pump. These devices combine the functionality of a pump and a generator to create a vacuum using compressed air directly. They typically handle lower volumes of air than traditional pumps but are useful for applications requiring intermittent operation or for tasks requiring a quick setup without additional equipment.

Key Benefits of Using Pneumatic Vacuum Pumps

Efficiency and Cost-Effectiveness

Pneumatic vacuum pumps are valued for their ability to increase operational efficiency. Using compressed air can often lead to lower operational costs as compared to electric pumps, especially in environments where compressed air is readily available. Their efficiency is also marked by the ability to operate continuously without overheating, making them suitable for various applications.

Low Maintenance Requirements

Another significant advantage is the low maintenance needs of pneumatic vacuum pumps. These pumps tend to have fewer moving parts compared to traditional electric pumps, which translates into reduced wear and tear over time. Regular maintenance mainly involves checking the air supply and ensuring that the system is free of any blockages.

Versatility Across Multiple Applications

Pneumatic vacuum pumps are incredibly versatile, capable of adapting to various applications across different industries. Whether it’s in packaging, material handling, or the medical field, their ability to produce a strong vacuum makes them ideal for diverse uses, including handling solids, liquids, and even gases.

Best Practices for Choosing a Pneumatic Vacuum Pump

Understanding Your Application Needs

Before selecting a pneumatic vacuum pump, it’s essential to clearly define the specific application’s requirements. Factors include the required suction force, the type of material being handled, and environmental considerations such as temperature and humidity levels. A thorough understanding will guide you toward the right pump specifications needed to meet your performance goals.

Evaluating Pump Specifications

When assessing pneumatic vacuum pumps, pay close attention to critical specifications such as suction capacity (measured in liters per minute), vacuum level (measured in Kilopascals or inches of mercury), and maximum operating pressure. These factors will significantly impact performance and efficiency, ensuring the pump aligns with your operational demands.

Supplier and Brand Considerations

The reputation of the supplier and the brand you choose can greatly influence the experience and the longevity of the pneumatic vacuum pump. Opt for well-established brands known for quality and customer support. Furthermore, consider potential warranties, repair services, and the availability of spare parts when making a decision.

Future Trends in Pneumatic Vacuum Pump Technology

Innovations in Design and Efficiency

The landscape of pneumatic vacuum pumps is evolving, with innovative designs focusing on efficiency and compactness. Future models are likely to feature enhanced materials that minimize friction and wear, leading to longer operational life and reduced energy consumption.

Sustainability and Environmental Considerations

As industries become more environmentally conscious, pneumatic vacuum pumps are also adapting to these demands. Many manufacturers are exploring ways to reuse conditioned air and optimize the energy consumption of their units, allowing companies to meet their sustainability goals without sacrificing performance.

Integration with Smart Technologies

With the advent of Industry 4.0, there is a growing trend toward incorporating smart technologies into pneumatic systems. This includes the use of IoT devices to monitor pump performance in real-time, predictive maintenance algorithms to reduce downtime, and remote operation capabilities that enhance control and efficiency.

Conclusion

Pneumatic vacuum pumps serve as vital tools that streamline processes across multiple industries. Their operational efficiency, low maintenance, and versatility make them a preferred choice in various applications. As we move forward, staying abreast of evolving technologies, benefits, and best practices will be critical for businesses looking to leverage pneumatic vacuum pumps as part of their operational framework.